The company's activities are focused on various aspects of foundry preparation.

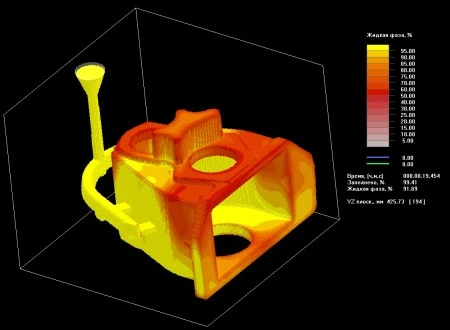

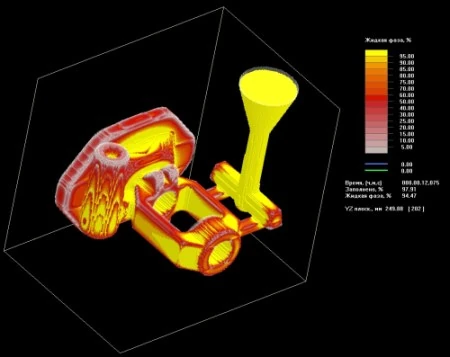

The engineering analysis is playing a key role as well as creation technologies and mathematical modeling of technological processes.

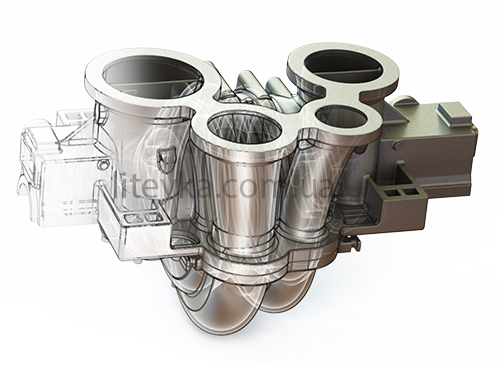

The specialists of the company have many years experience in advanced CAD/CAM/CAE systems for the preparation and optimization of various production technologies.

Initial materials for design:

The casting technology into the ground, chill mold, lost-foam casting, lost-wax casting is calculated using modern technological programs. It makes possible in theory to detect casting defects and in practice to reduce defects to a minimum.

The company is equipt with numerical control (CNC) machines. It allows to manufacture tooling of any complexity with high prescision and in short terms.

The following tooling can be designed and manufactured

The company can produce foundry products, castings from iron, steel, non-ferrous metal

The company has shops for casting in the ground, casting for cold-hardening mixtures. As well as a shop for precision casting of burnt-out models.

Preparation of all technical information for the development of the foundry:

The company's specialists have practical production experience in organizing new production facilities, mastering technologies and putting into production various products and castings of high complexity.

2009 - «Foundry tooling» company